Graders (Then and Now) and a Few Things Every Operator Needs to Keep in Mind

Posted: June 11, 2020 by Argo Road Maintenance

Earlier this week, we spoke to Reg Wetherill about his experiences working in roadside construction zones. Reg has worked on northern BC roads and highways for 46 years – first as a surveyor and then in road maintenance. So, we asked him to tell us a little bit more about the equipment, how it’s changed over the years, and what an operator needs to think about on the road.

Ready for a trip through time?

You’ve been doing this work for a long time – 39 years! Has it changed a lot?

The suspension and the power [of the equipment] has definitely changed, but the actual work hasn’t.

Ok, we’re going to get to the equipment, but for those of us who have never driven a grader, what does it do?

A grader smooths out the road surface by using a large blade (located under the machine) to scrape out ruts and remove potholes. In the wintertime, the blade pushes the snow off the road; and because the grader is less bulky and has a smaller blade [than a plow truck], it can do jobs that require more finesse like clearing turnarounds and pushing drifts back.

Cool! Ok, so you mentioned that the equipment has changed a lot and you even have a few pictures. Would you tell us a bit more about the graders in these photos and the changes you’ve seen over the years?

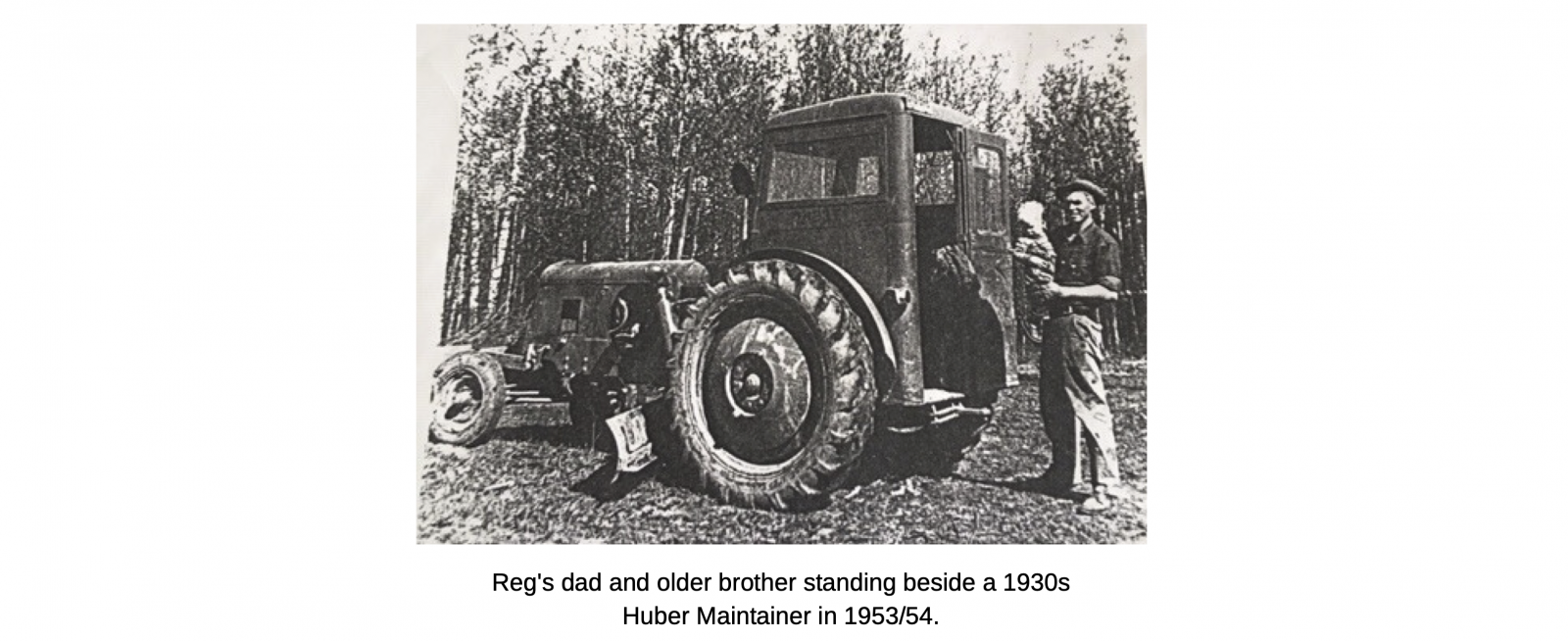

This is my dad and older brother standing beside a Huber Maintainer Grader in 1953/54. This type of grader was originally built in the 1930s. But, it was pretty new, pretty advanced for our area when this photo was taken. (We were further behind for getting hydro and roads up here, because we’re over the mountains so it’s harder to get stuff here.)

My dad used this one in the Progress maintenance area. They used it a bit in the wintertime to plow little snowstorms, but it was mostly for grading ruts in the roads because very few roads in the area had gravel, let alone pavement. During this time, if there was a big snowstorm, the ministry would bring in CATS to open the roads.

Was there a seat? It looks like your dad might have had to stand in it?

No, there’s a seat in there too, but lots of grader guys would stand up because you couldn’t see the blade [sitting down]. When I started grading in 1981, when I started learning, my mentors always said, “sit down.” You learn to sit down because if you stand, your spine would take all that jarring, and your back and legs would be in rough shape when you’re older. Some of the old grader guys could hardly get out of their graders, so I learned to run the grader sitting down.

And each year they made the cabs better. These new 160M graders, they’re beautiful. They have air conditioning, more power, better suspension, and bucket seats. You can see the whole blade sitting down. They’ve advanced a lot that way.

I imagine being able to see the whole blade gives you more control?

Yeah, for sure. Before you were kind of searching and going by feel, and now you can see every little move, so you have way better control. And we have air conditioning. With the old graders, we used to open both doors and let the air blow through. It was like a sauna in there.

I had an old grader friend (he was around 80) he died of lung disease from eating too much dust. A lot of farmers and grader operators did because they ate dust every day. Come quitting time, the only things that were white were your eyeballs and teeth.

Did the graders your dad drove have heat?

Very little. It would come off the engine. It wouldn’t be an actual heater that you turned on. You would still freeze, but not to death. There’s better climate control in our equipment now, that’s for sure.

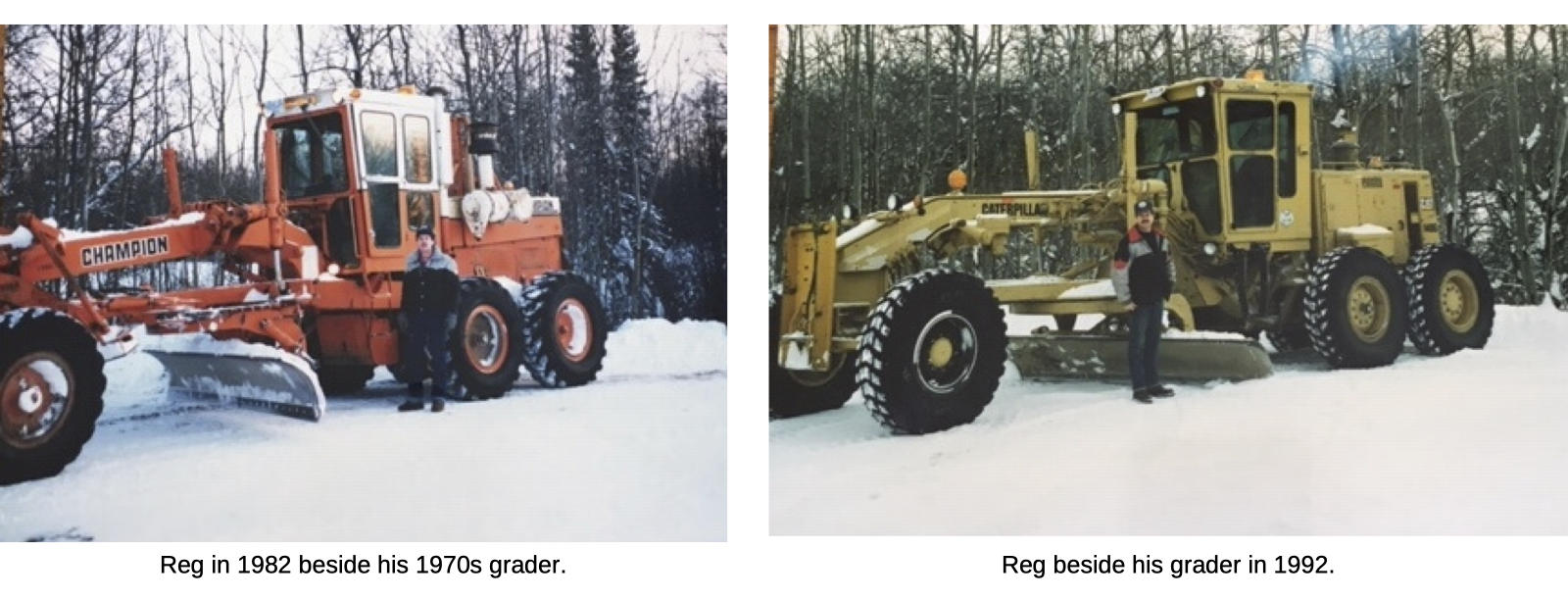

What about the graders in these next two images?

This first one, the orange one, is a 1970s machine. It wasn’t very fancy: It had an old bench seat, no air conditioning, and very little power. The second one, the yellow one is from 1992. It was a pretty fancy grader: It had a bucket seat, more power, and air conditioning.

And, these new graders, the ones you’re driving now – the 160Ms with air conditioning and bucket seats – what makes them so exciting to drive?

Power and visibility. And these new ones, they don’t have a steering wheel. They’re joystick driving and operating. So, it’s way less work in the cab. You’re not moving your hands all over. You put them on the controls, and they stay there, so it’s less work for the operator. Every new grader that comes out they improve – how easy they are to handle, the power, the traction, they’re always improving.

It’s amazing how big and complex these machines are – and how much they’ve improved over the years.

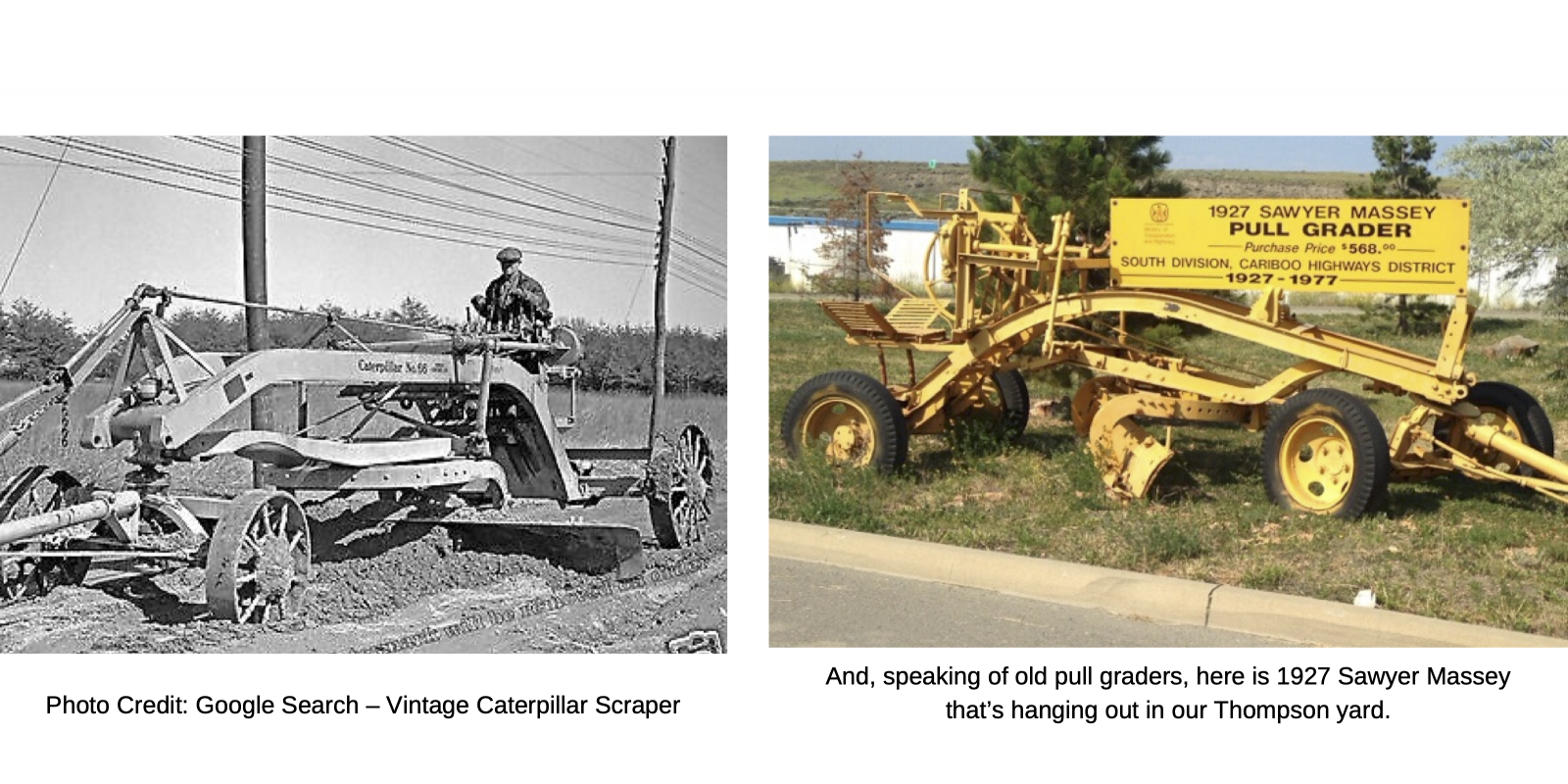

Yes, early on in my career, I also ran a pull grader. It was used to build and rebuild roads and was pulled by a big 4x4 tractor or D8 CAT. I helped build Irby Road and rebuild Wangler Road with one of these. I don’t have a picture, but the one I ran looked very similar to this one.

Wow, that looks challenging to operate. And, the new ones, even with all the equipment improvements, I imagine it’s still pretty draining work?

Yes, at the end of a long day – especially in the wintertime when a lot of us don’t stop for lunch and breaks and just go, go, go – you’re drained at the end of your shift.

How many kilometers do you do in a typical day?

It depends on your experience. In the wintertime, I do 100km or 120km (sometimes 130km) a day – but that’s just experience and knowing the area.

When I first started, I would do around 40 km a day. With experience, you learn what to look out for, where to slow down, when to speed up, and how to read the equipment. So, when I was younger, I had to learn all that. One big part of my job was being mentored by the older guys, and now that I’m an older guy [Reg, you’re not that old, you’re only 64], I try to return the favour.

What are some of the things you’ve learned with experience? What advice would you give to new operators?

Expect the unexpected, take your time – don’t overwork the equipment, and always have a plan B. If you get hit by a distracted driver, if you’ve overworked your equipment and have to take it back to the shop, or if you’ve gotten stuck navigating a particularly challenging turnaround, you’re not getting the roads maintained, and somebody can’t get home or to work.

You always need to be alert and watch for drivers not paying attention. Learn the roads: know where the ditches are, where the culverts are, and where the challenging turnarounds are so that you can anticipate and navigate them effectively. Take your time and remember that there are two aspects to this work: doing it and taking care of it [the equipment]. For example, if you’re grading in the summertime and push too hard, you burn too much fuel, the tires wear out, and the road looks bad. I always tell the guys, “just take a little bit. You do what the equipment can do and then take another round or two or whatever it takes.”

And, safety, safety, safety. As I get older, I learn that safety takes longer. Cutting corners (whether it’s for good reason or bad reason), might get the job done faster, but we need to work safely. Safety as our first priority might take a bit longer, but at the end of the day the job will be done better, and everyone will make it home safe.

Thanks, Reg – for keeping our roads and our crews safe. And, drivers, thank you for being patient and keeping your distance when you come across slow-moving vehicles like graders. We know we’re going slow – we want to make sure we get the job done right and that we all stay safe. When you slow down and give us room to work, you’re not only giving us the space we need to do our jobs well, you’re also doing your part to ensure we make it home to our families. Thank you.